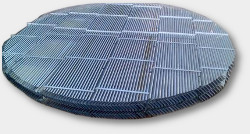

VANE Mist Eliminators

|

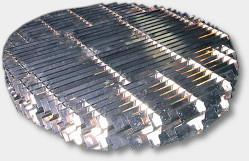

Vane (chevron) mist eliminators are widely used for the separation of liquid droplets from a gas stream. They consist of zig-zag chevron blades spaced usually on a 1", 1½" or 2" pitch.

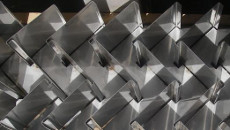

The blade profile can be smooth (for non fouling services) or with hooks (for greater removal efficiency and capacity).

|

The blades are normally 2 pass, 3 pass or 4 pass. The number of passes corresponding to the number of times the gas flow changes direction. As the gas passes through the demister and changes direction the liquid droplets due to their momentum are unable to change direction as quickly and thus impact on the chevron blades where they coalesce and form larger droplet which then drain away.

|

|

Compared to mesh demisters DtEC vane type demisters offer the following advantages:

- Higher capacity

- Blades with a smooth profile will give 30% more capacity than a mesh demister

- Blades with hooks will give 100% more capacity than a mesh demister

- Higher liquid loading

- Less risk of fouling

- Lower pressure drop

- Longer lasting in service

- Suitable for foaming systems

- Suitable for high liquid viscosity systems

- Stronger construction

|

With smooth profile blades typical removal efficiency is 100% removal of droplets 17µ and greater in diameter. Using blades with hooks the normal removal efficiency is 100% of droplets 10µ and greater in diameter.

As with the mesh demisters the vane demisters are supplied in a wide range of materials both in metal and plastic.

Flow configuration is either for vertical or horizontal gas flow through the chevron demister . In some application an inclined arrangement is used to facilitate the drainage of liquid. For horizontal gas flow the capacity is 30% greater than in for vertical flow.

|

Construction normally is in segments for installation through column man-holes. In such cases the demister is supported on a full support ring welded to the column shell.

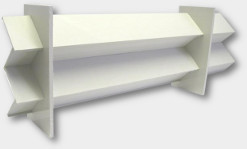

Alternatively, the vane demister can be supplied complete enclosed in a frame as a "Vane Pack" which can be flanged for direct attachment to a baffle plate within the vessel.