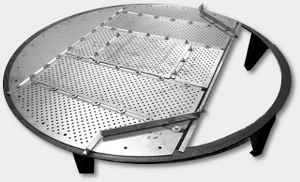

Sieve Trays

Whether you are designing a new column, revamping an existing column or just carrying out maintenance, whatever your requirement is for trays, we have the answer.

We design, manufacture and install all types of trays including, but not limited to, dual flow trays, baffle trays, disc and donut trays, sieve trays, valve trays, bubble or tunnel cap trays.

Let our considerable experience and expertise assist you in making and implementing the most appropriate solution, at minimum cost, not only to achieve the desired throughput but also to accommodate feed rate variations and minimise downtime.

|

Sieve trays are the basic type of fractionation tray, typically using ½" diameter holes with an open area between 5 to 15%.

They have a moderate pressure drop with average capacity & separation efficiency.

Sieve trays offer a key advantage of cost. However, flexibility is limited to 2 to 1 and in addition sieve trays are not suitable for fouling services.

Bubble Cap Trays

|

Bubble cap trays are used in applications with very low liquid loading and requiring a very high flexibility (e.g. an operating range of 10 to 1) such as in batch distillations.

Bubble caps are either slotted type or un-slotted type, both in a full range of sizes (2"nb to 6"nb).

Bubble cap trays have a high pressure drop with low capacity & separation efficiency. They are not suitable for fouling services