Packed columns using random or structured packing require complementary internals. At DtEC we have the answer to your requirement for all packed tower internals since we design, manufacture and install a full range of internals suitable for all packing types and column diameters.

DtEC design standards are based on many years of proven experience in the mass transfer field and are used to custom design the internals to suit the specific process requirements, resulting in consistent and reliable column performance.

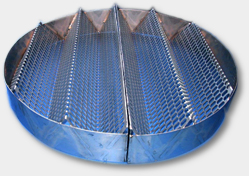

Packing Support Plates

|

|

|

To support a bed of random packing the most common type of packing support plate used is a gas injection multi-beam type which can be designed to support loads of 5000 kg/m2 or more.

Our Model 100 gas injection multi-beam packing support plate is used for small diameter columns between 300mm to 1200mm.

Two piece construction is used for column diameters between 300mm to 850mm for installation through column body flanges. Three or four piece construction is provided for column diameters between 851mm to 1200mm, with installation through column man-holes.

A partial support ring or wall clips welded to the column shell are required for supporting the plates. The packing support plate sections are bolted to each other inside the column and clamped to the support ring or wall clips.

Our Model 110 packing support plates are used for column diameters greater than 1201mm. They provide a free area of approximately 100% and are designed to be clamped to full support rings welded to the column shell. For column diameters 3000mm and greater major support beam(s) are used. Installation is through column man-holes.

For special applications such as liquid - liquid extraction columns, a perforated plate support plate c/w risers are used.