The separation of liquid droplets entrained in a vapour (gas) stream is a key requirement in many process operations to improve the performance of the plant (capacity & purity), to protect downstream equipment , to reduce the loss of valuable chemicals or to comply with stringent environmental protection regulations.

At DtEC we have a full range of mist eliminators (demisters) to ensure tailor made solutions for your applications.

Both mesh and vane type demisters are designed to achieve an optimum gas velocity to maximise removal efficiency. Too high a velocity will result in re-entrainment of the liquid droplets whilst too low a velocity will allow very small droplets to pass straight through the demister.

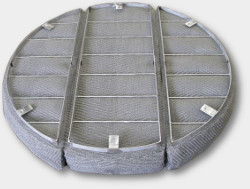

MESH Mist Eliminators

|

Mesh pad mist eliminators remove liquid droplets by impingement of the droplets on the wire surface. The droplets agglomerate and increase in size until they are sufficiently large enough to drain from the pad by gravity.

Mesh demister efficiency is primarily a function of droplet size, wire size, specific surface area of the mesh, pad thickness and physical properties of the system. For a standard specification mesh demister (wire Ø 0.28mm, density 145 kg/m3, surface area 300 m2/m3) removal efficiency is typically 100% for droplets 5µ and greater in diameter. Higher surface area mesh demisters 500m2/m3 using a reduced wire diameter 0.15mm can be used to improve the removal efficiency.

|

Mesh demisters can be installed either horizontally or vertically. With horizontal gas flow through the demister the capacity is 30% greater than compared to vertical flow, thus the demister can be smaller.

Mesh pads are typically 150mm thick with 25mm thick grids on either side making an overall thickness of 200mm.

Many years of experience have shown that a 150mm pad thickness provides optimum performance in hydrocarbon processes with a vertical gas flow configuration.

|

Mesh demisters are made from pads of knitted metal wire or plastic wire. The pads are held between top and bottom grids. For vessel diameters greater than 600mm the demister is split into segments to allow installation through column man-holes. The overall diameter of the assembled pads is greater than the vessel diameter to ensure a snug fit thus eliminating any vapour bypass at the periphery or between adjacent segments.

Standard grids are made from 25mm x 3mm thick bar c/w 6mm diameter rods on a spacing of 150mm. Heavy duty grids can be provided for special applications. The grids have been specially developed to give a very high percentage open area.

The DtEC range of mesh demisters are made in a wide range of materials both metal and plastic:

| Stainless Steels | (e.g. 304/304L, 316/316L, 321) |

| Duplex Stainless Steels | (e.g. 2205) |

| Higher Alloys | (e.g. 904L, nickel, alloy C276, alloy 400, alloy 625) |

| Glass Wool or Fibre |

| Polypropylene |

| PTFE |